Maintenance and Support

You May Also Be Interested In

1270G 8W video in Scotland

1270G Wheeled Harvesters

- Effective, versatile and productive

- Strong and accurate harvester heads

- CH7 harvester boom

- Pleasant working environment

Harvester heads

John Deere harvester heads are known for their productivity, reliability and especially accuracy. The harvester heads have efficient feeding and delimbing.

Product program

Product Program wheeled cut-to-length

Over-rotation prevention protects against hose damage.

Over-rotation prevention is available for 1270G and 1470G harvesters with IBC 3.0 and H424 or H425/H425HD harvester head.

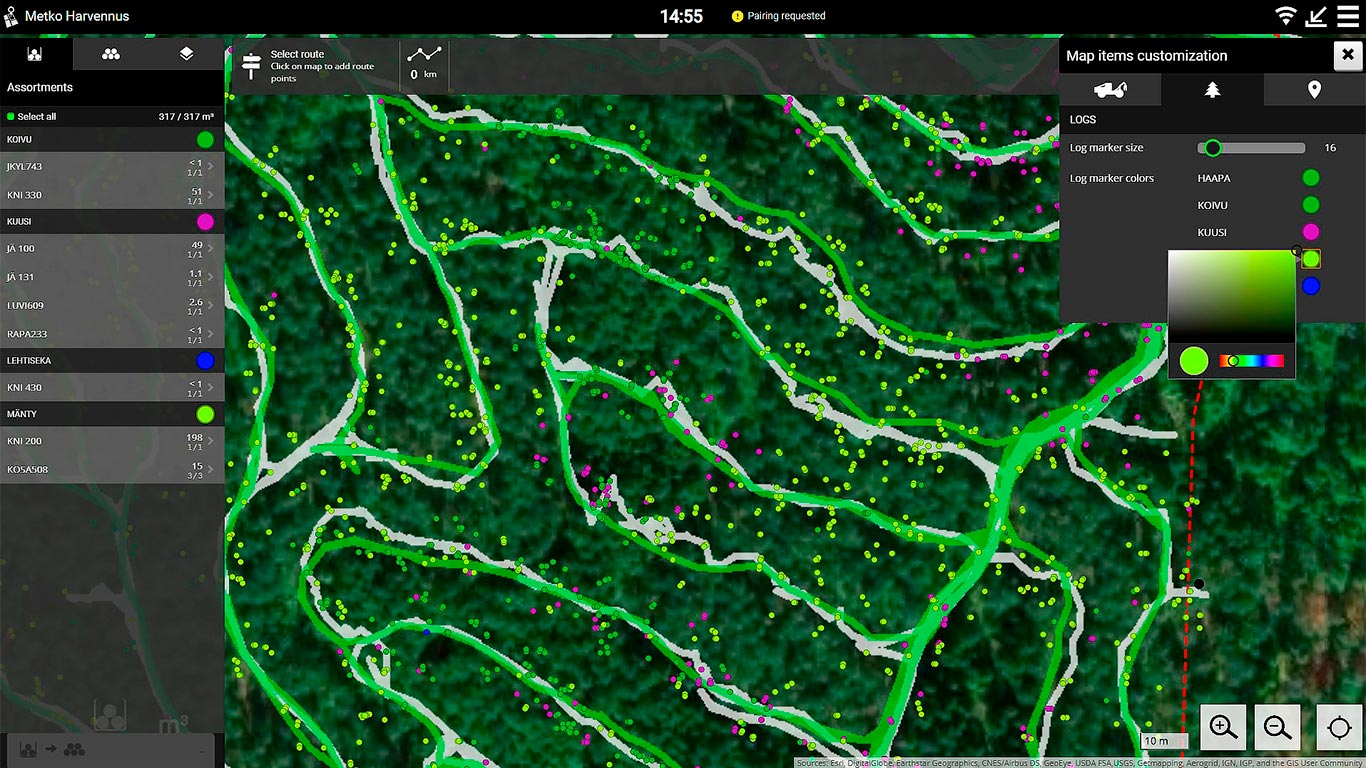

TimberMatic Maps gives operators a real-time production view to the logging site.

The data collected by the harvester’s sensors and the precise GPS-based location of the felled timber, is automatically transmitted from the harvester to the TimberMatic Maps application for use by the forwarder operator.